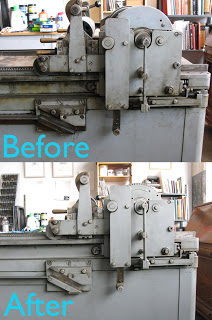

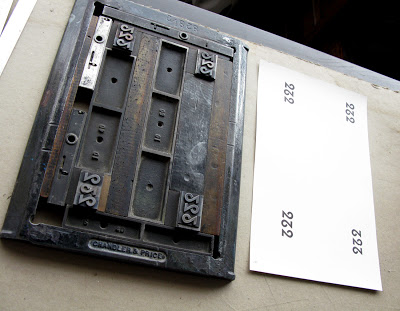

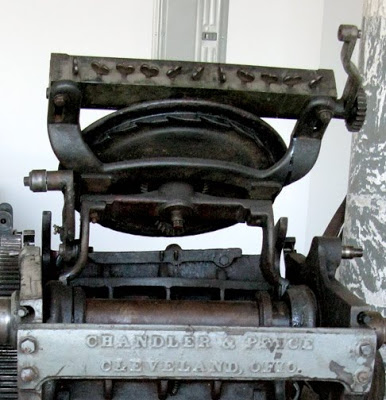

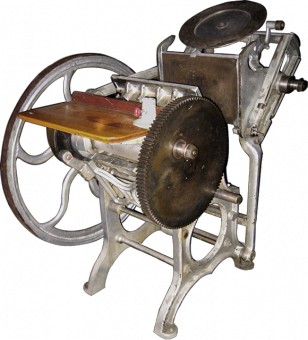

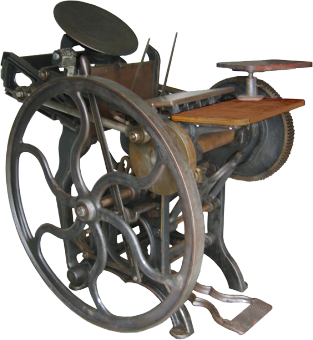

At the Common Press, where I work, we were just given this press, but we're not quite sure what it is exactly... It was described to use as a plate press, and when I did a little research, I found similar looking presses that were called arming or embossing presses. If it is one of these, I'm wondering if there used to be some sort of heating mechanism and how it could be restored.

The only other clue here is that the maker's name is E. Ermold of New York. I did find some old printing trade publications that mentioned his name and that he sold embossing presses, but no images.

If you know anything about how this press might work, I'd be interested to learn more. Thanks!

:: new mystery press ::

:: E. Ermold ::